Switchgear Services

Our team has qualified Technicians / Engineers with expert knowledge being provided to upgrade their knowledge of latest products.

HV Breaker Services: (Vacuum circuit breaker & Sf6 Breakers)

- Preventive maintenance of HV Breakers

- Overhauling and Servicing of HV Breakers

- Annual Maintenance Contract (AMC) of HV Breakers

- Testing of HV Breakers

- Supply and fixing of HV Breaker(VCB & Sf6) Spares.

- Retrofitting of HV Breakers

- Trouble Shooting.

Air Circuit Breakers (ACB)

- Supply and fixing of ACB & ACB Spares.

- Preventive maintenance of ACB.

- Overhauling and Servicing of ACB

- Annual Maintenance Contract (AMC) of ACB

- Testing of ACB.

- Retrofitting of ACB.

- Trouble Shooting

Moulded Case Circuit Breakers (MCCB)

- Supply and fixing of MCCB.

- Servicing of MCCB.

- Retrofitting of MCCB.

- Testing of MCCB.

- Trouble Shooting.

STARTERS (Industrial and Domestic)

- Supply and fixing of Starters.(Star&Delta, DOL)

- Control and Power Wiring of Starters.(Star&Delta, DOL)

- Retrofitting of Starters.

- Testing of Starters.

- Trouble Shooting.

Electronic Metering Devices:

- Supply and fixing of Electronic Metering Devices.

- Retrofitting of Electronic Metering Devices.

- Testing of Metering Devices.

- Trouble Shooting

Digital Protective relays:

- Supply and fixing of Digital Protective relays.

- Retrofitting of Digital Protective relays.

- Testing of Relays.

- Trouble Shooting

Switch Fuse Units & Change Over Switches:

- Supply and fixing of SFU &Changeover Switch.

- Retrofitting of SFU &Changeover Switch.

- Trouble Shooting.

Contactors

- Supply and fixing of Industrial Contactors.

- Retrofitting of Contactors.

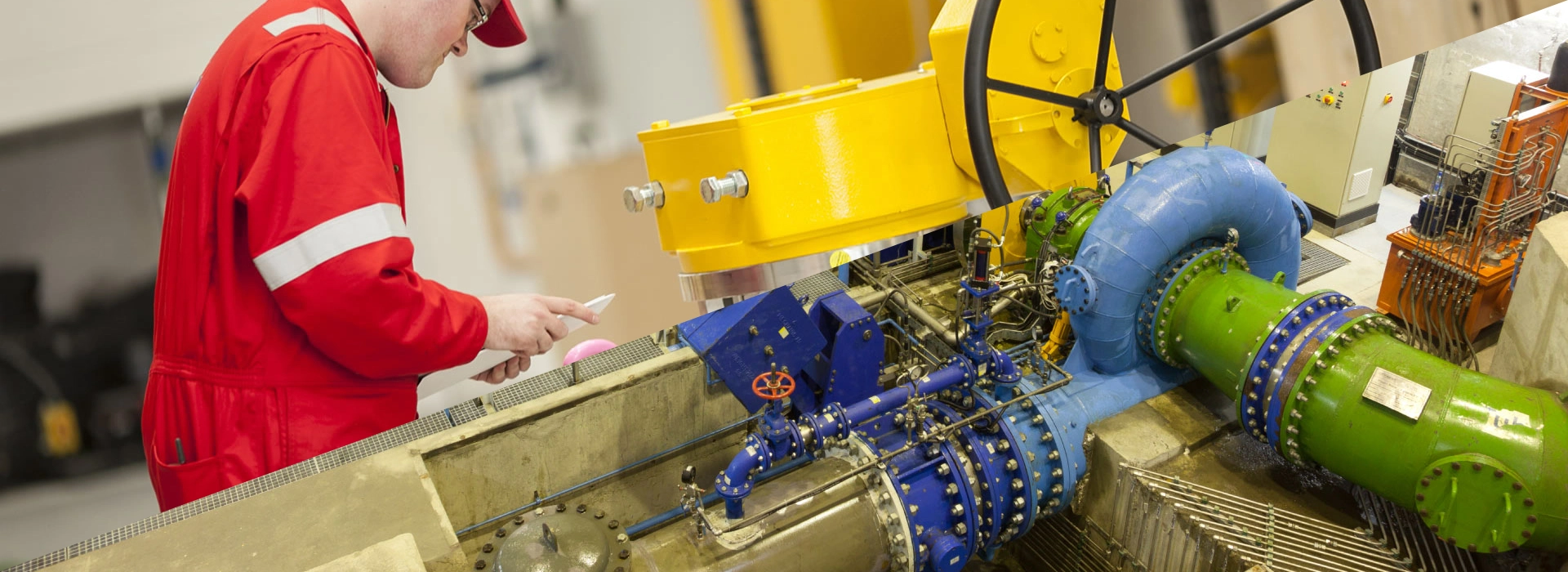

Mechanical

Overhauling & Breakdown

- Refurbishment of Boilers and Auxiliaries like repairs, modification and revamping for Boilers.

- Rehabilitation of pressure parts, mill system, rotary equipments, rotary parts and ducting.

- HP & LP piping works.

- Repair & restoration of ESP components.

- Operation & Maintenance of CHP.